Combining CNC Milling & Turning for Complex Parts

Share Post

Combining CNC Milling & Turning for Complex Parts

In the turned parts manufacturing process, CNC milling and CNC turning are two important ways to make precise parts. Each method has its own strengths: CNC milling operations work well for flat surfaces and detailed designs, while CNC turning is ideal for round shapes. But when these machining methods are combined, manufacturers can create even more complex shapes with higher accuracy, faster production, and lower costs. Here’s why combining computer numerical control (CNC) milling and turning is a smart choice for complex projects.

Precision with CNC Milling and Turning

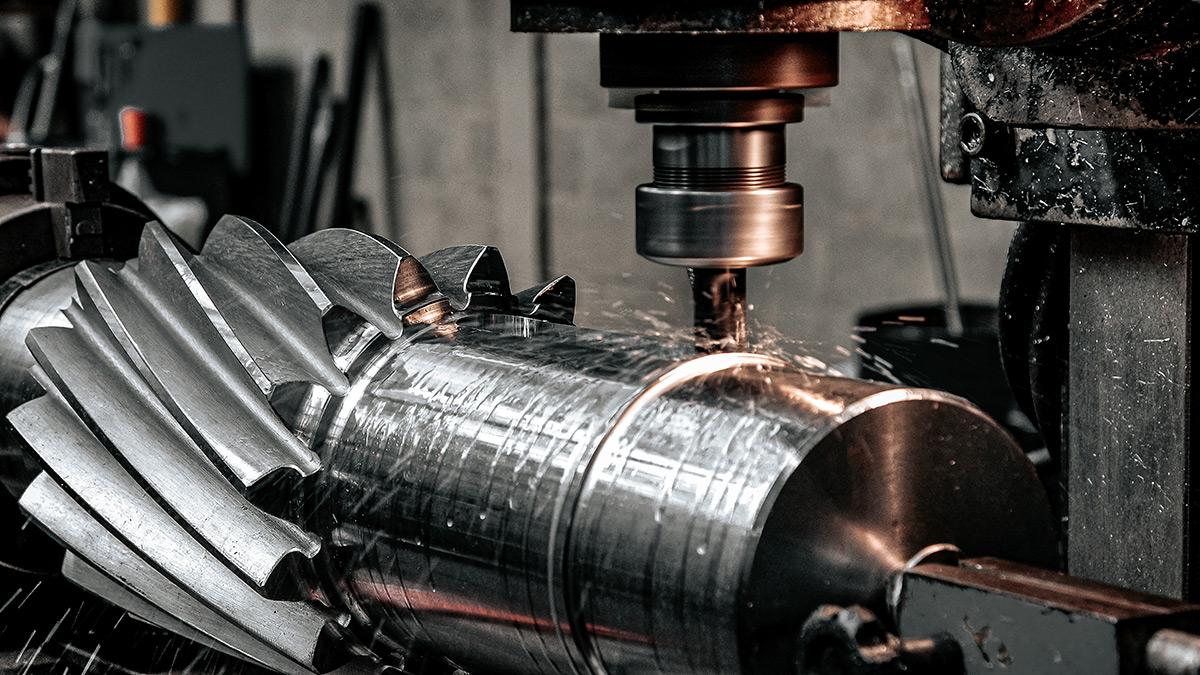

When a part needs both flat and round surfaces, combining CNC milling and turning makes it easier to shape each area with high precision. CNC milling machines can handle detailed, flat surfaces, while CNC turning creates smooth, rounded parts. Using both methods together means each feature is crafted exactly to design, without moving the material to a different machine. This reduces the risk of errors and helps make complex parts more accurate.

For parts that require very precise measurements, like automotive parts, combining milling and turning ensures each part meets strict quality standards. With fewer adjustments needed, manufacturers rely on this approach to produce parts that fit the desired shape.

Faster Production with Fewer Setups

Combining CNC milling and turning also saves time. Normally, moving a part between machines for separate milling and turning steps slows down production and requires extra setup. But when both methods are used in one workflow, there’s no need to transfer parts between machines, which makes production faster and simpler.

This streamlined process also reduces the risk of handling mistakes, which can happen when parts are repositioned. By cutting out extra steps, manufacturers can complete projects faster and meet deadlines more easily. This time-saving approach is especially useful for projects that need high accuracy and fast turnaround.

Flexibility with Different Materials and Designs

Using both CNC milling and turning together adds flexibility to the process. Both methods work with materials including metals and plastics, and other common materials, so manufacturers can use this combined approach for a wide range of projects. Combining these methods also makes it possible to create parts with unique designs.

Many complex parts have a mix of flat surfaces, curved edges, and round sections. With milling and turning in one workflow, manufacturers can remove material from a workpiece with various shapes without sacrificing quality. This combined approach allows for creative and functional designs that would be hard to achieve with only one method.

Cost Savings with Fewer Setups

Keeping costs low is key for many manufacturers, and a combined milling and turning approach helps with that. With fewer setups and less material handling, manufacturers save time and reduce labor costs. There’s also less risk of errors and wasted materials, which can add to production costs.

This efficient approach keeps projects moving with fewer interruptions, which is helpful for both small test runs and large production orders. By cutting costs while maintaining quality, combining CNC milling and turning is a smart choice for complex projects.

Is a Combined CNC Approach Right for Your Project?

Combining CNC milling and turning is a great option for projects that need precise parts made quickly and affordably. This method allows manufacturers to create parts with flat and round surfaces in one smooth process, saving time, reducing waste, and allowing for a variety of materials and designs. CNC lathes use point cutting tools to create cylindrical parts with smooth, precise finishes.

If you’re interested in using CNC milling and turning for your projects, In-House CNC has high-quality machines that make it easy to handle complex projects. Contact In-House CNC today to learn more about our machines and how they can help you produce accurate, reliable parts with ease.

Ready to achieve next-level precision in your CNC projects? Reach out to In-House CNC at (951) 540-4820 or sales@in-housecnc.com to explore how we can support your goals for accuracy and reliability. Our team is committed to providing high-quality CNC machining solutions that deliver precise results every time!