How Metal Fabricators Serve Different Sectors

Metal fabricators play a vital role in creating essential parts for many industries. Their work ranges from making sturdy car frames to producing precise components for medical equipment.

Using a variety of metals and specialized techniques, metal fabricators shape, cut, and assemble parts that meet the unique requirements of each sector. Whether it’s the strength needed in construction materials or the precision required in healthcare tools, each industry relies on specific metal parts to function safely and effectively.

Skilled metal fabricators have the training and knowledge to produce these custom parts, ensuring they meet exact standards and quality. Without metal fabricators, many industries couldn’t operate as efficiently or meet the safety and durability standards that are essential in today’s world.

Training and Skills for Metal Fabricators

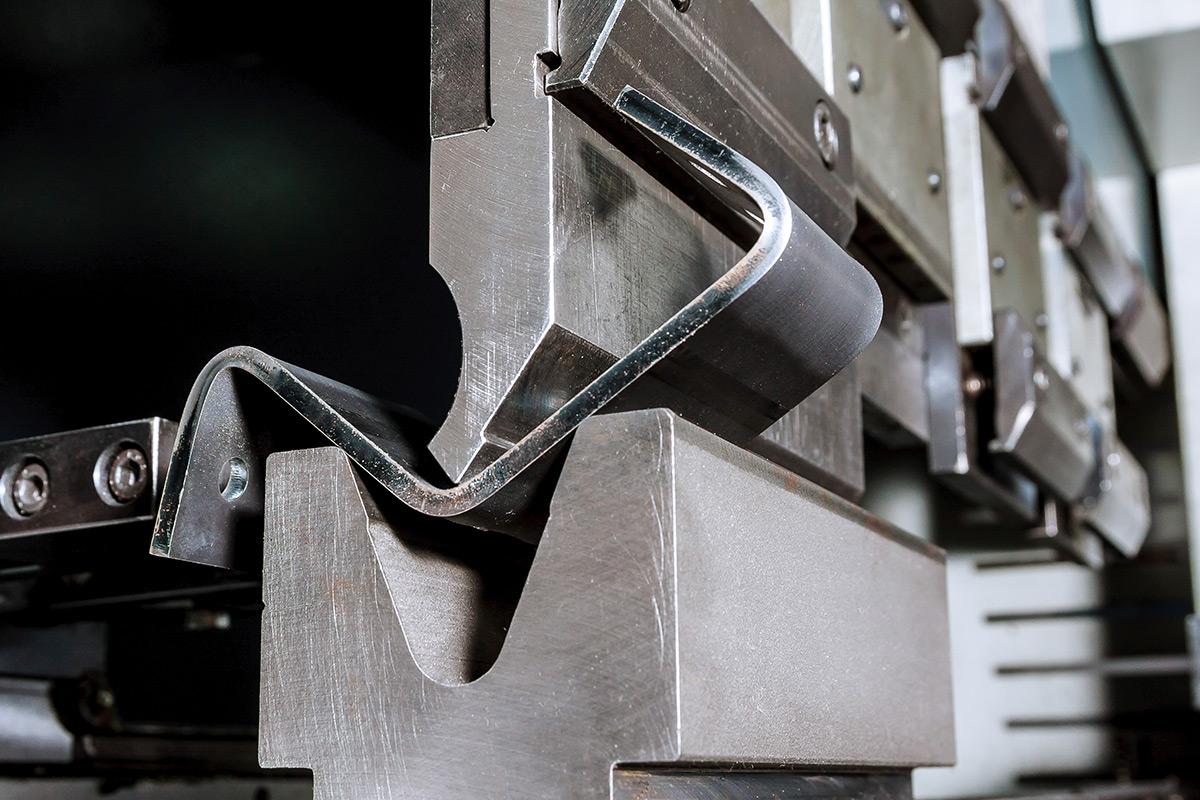

To make all these custom parts, metal fabricators go through special job training. They learn blueprint reading and how to work with different metals like structural steel and sheet metal. Fabricators also learn how to use advanced tools, like press brakes, which help them shape and cut metal with high precision

This training ensures that they can make parts that meet the strict needs of industries like aerospace and healthcare. Fabricators’ skills allow them to create safe, reliable parts that support many essential services.

Automotive Industry

The car industry needs strong and durable parts. Metal fabricators make car frames, engine mounts, and exhaust systems that can handle daily use. They often use structural steel because it’s tough and holds up well under pressure. To shape the metal into exact forms, fabricators use machines like press brakes to bend the metal precisely.

They also read blueprints to make sure each part fits perfectly within the car’s design. These custom parts help cars stay safe and reliable on the road, even after years of use.

Aerospace and Defense

In aerospace and defense, parts need to be both lightweight and strong. This is especially important for airplanes, which need to be safe and efficient. Metal fabricators use sheet metal and other lightweight metals to create airplane parts. Fabricators cut and shape these metals to exact measurements.

Fabricators use steel fabrication to make parts like turbine blades and engine casings, which must withstand tough conditions. They build each part to strict standards to handle high speeds and extreme temperatures.

Construction and Infrastructure

In construction, metal parts provide the strength needed for buildings, bridges, and transportation systems. Structural metal fabricators make beams, supports, and frameworks from structural steel and other durable metals. Construction fabricators use tools to cut and bend the metal so it fits the exact needs of the project.

They also use welding wire to join parts securely, ensuring that buildings and bridges are safe and stable. Each part must pass safety checks to support the weight and stress of large structures.

Electronics and Consumer Goods

Metal fabrication helps make parts for electronics and other everyday items. Fabricators use sheet metal to create thin, sturdy cases for electronics like phones and computers. These cases protect the delicate parts inside and make the devices last longer. Fabricators also treat the metal to prevent rust, which keeps parts durable.

In the electronics industry, fabricators must work with precise measurements so that each part fits properly into the final device. The careful design and durability of these parts help keep consumer goods reliable.

Medical Equipment

Metal fabricators also make parts for medical devices. Hospitals and clinics need specialized metal parts for tools like surgical instruments and diagnostic machines. Fabricators must make these parts with high accuracy to ensure safety. Fabricators use metal materials that meet health standards and make sure each piece fits perfectly within the device.

The parts must be reliable since they’re used in healthcare, where safety is a top priority. This precision ensures that medical equipment can support doctors and nurses in patient care.

The Ongoing Impact of CNC Machining on Modern Manufacturing

Metal fabricators play an essential role across many industries by creating custom parts from raw materials to meet specific needs. From strong car frames to precise medical tools, fabricators provide solutions that keep different sectors operating smoothly. They apply skills in steel fabrication, precise cutting and bending, and using welding wire to ensure each part is reliable and meets exact standards.

For businesses that require custom metal parts, skilled fabricators are valuable partners. Their expertise helps industries maintain high safety and performance standards, offering durable solutions tailored to each application. Contact us today to learn how our metal fabrication services can support your industry’s unique needs.

For industries that rely on precise, custom metal parts, In-House CNC is here to help. Contact us at (951) 540-4820 or sales@in-housecnc.com to discuss how our CNC machining methods—whether milling, turning, or a combination of both—can meet your project’s exact needs. Our team specializes in producing reliable, high-quality parts crafted to meet the standards of any industry, from automotive to healthcare. Reach out today to learn how our expertise in CNC solutions can support your operations with accuracy and durability.