How CNC Machining Delivers Complex Geometries with Ease

CNC (Computer Numerical Control) machining has completely changed the way industries make parts. Instead of using manual tools, CNC machines use computers to cut and shape materials with extreme precision. This makes it easier and faster for CNC machining to deliver complex geometries.

Industries like aerospace, automotive, and medical technology rely on CNC machining to make high-quality parts with exact measurements.

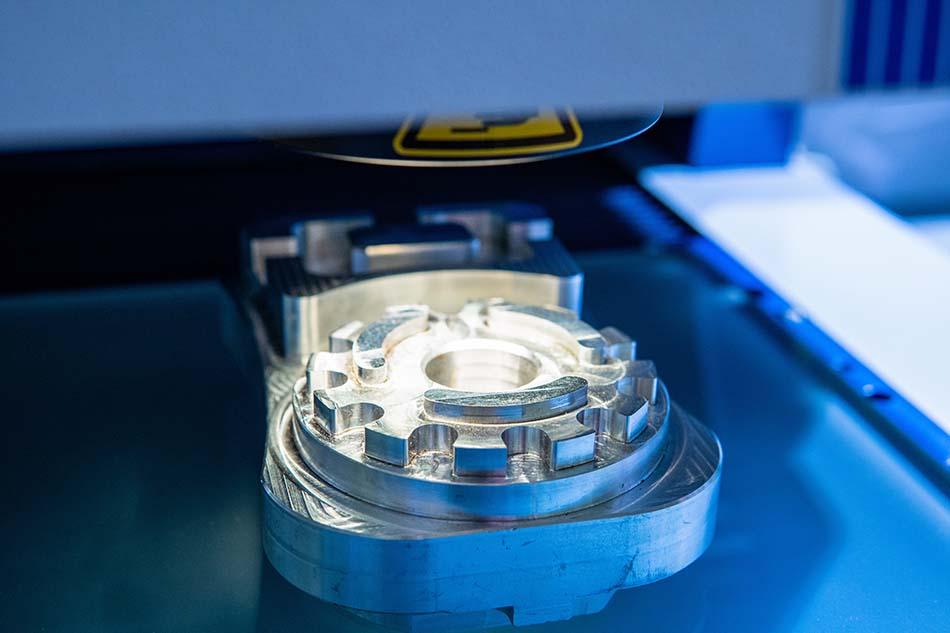

cnc machining delivers complex geometries

Precision & Automation Make CNC Machining Stand Out

The ability to design, test, and manufacture intricate parts quickly has given CNC machining an advantage over traditional manufacturing processes. Understanding how CNC machines work helps explain why they are essential for creating complex CNC machined parts with ease.

One of the biggest advantages of CNC machining is its accuracy. Older machining methods depended on human skill, which sometimes led to errors.

CNC Accuracy: Making Or Breaking Contracts

One of the biggest advantages of CNC machining is its accuracy. Older machining methods depended on human skill, which sometimes led to errors. CNC machines, however, follow exact instructions from a computer, ensuring that every cut, hole, and shape is made perfectly. This automation means parts can be made consistently without variation.

CNC machining can work with extremely tight tolerances, meaning parts fit together perfectly. This is especially important in industries like aerospace, where even a tiny mistake can cause major problems. The ability to create precise components without manual adjustments makes CNC machines ideal for producing intricate designs.

Another major benefit is that CNC machines can easily handle both small and large production runs. Whether making one prototype or thousands of identical parts, CNC machines maintain the same high level of accuracy. This is especially useful in industries where precision and reliability are critical, such as in making medical implants or aircraft components.

Multi-Axis CNC Machines Can Create Complex Designs

CNC machines come in different types, based on how they move and cut materials. The more movement (or axes) a machine has, the more detailed the shapes it can create.

- 3-Axis CNC Machining: Moves the cutting tool up, down, and side to side. Best for basic shapes.

- 4-Axis CNC Machining: Adds rotation around one axis, allowing for more angles and complex designs.

- 5-Axis CNC Machining: Moves in five different directions, making it perfect for highly detailed and curved shapes used in medical and aerospace industries.

Having multiple axes allows CNC machines to cut from different angles without needing to stop and reposition the material. This saves time, improves accuracy, and ensures high-quality results. Industries that need intricate and smooth complex parts, like aerospace and medical device manufacturing, depend on multi-axis machining to get the job done right.

How Software Helps CNC Machines Make Detailed Parts

CNC machining depends on specialized computer programs to control the machines. Engineers use Computer-Aided Design (CAD) software to create digital blueprints of parts. These designs are then processed by Computer-Aided Manufacturing (CAM) software, which translates them into step-by-step machine instructions.Advanced software allows CNC machines to create:

- Deep, hard-to-reach cuts that manual tools cannot easily make.

- Smooth curves and flowing designs for parts like turbine blades and medical implants.

- Precise hole patterns and threading to ensure parts fit together correctly.

- Unusual designs that would be difficult or impossible to create by hand.

Using software eliminates mistakes and makes it possible to test designs before cutting begins. Many CNC software programs can simulate the machining process, helping detect potential problems early. This reduces wasted materials and ensures that every part is made correctly the first time.

CNC Machining Works With Many Materials

CNC machines are incredibly versatile because they can cut and shape a wide range of materials. Some common materials used in CNC machining include:

- Aluminum: Lightweight, strong, and commonly used in airplanes and cars.

- Titanium: Very strong and corrosion-resistant, often used for medical implants and aerospace applications.

- Stainless Steel: Durable and resistant to rust, ideal for medical tools and food-grade equipment.

- Plastics: Used for lightweight prototypes and custom CNC machined parts.

- Carbon Fiber and Composite Materials: Found in sports equipment, high-performance cars, and aircraft parts.

The ability to work with different materials makes CNC machining valuable across many industries. Even very tough metals, such as Inconel (used in jet engines), can be precisely shaped using CNC technology. CNC machining makes it possible to cut, drill, and shape materials that would be difficult to work with using traditional methods.

Faster Production and Cost Efficiency

CNC machining is one of the fastest ways to manufacture parts, making it a great choice for industries that need efficiency and precision. Unlike older machining methods that require human workers to manually guide tools, CNC machines run automatically. Once programmed, they can operate 24 hours a day, 7 days a week, producing large quantities of parts without stopping.

Since CNC machines don’t need breaks, companies can make products much faster than with manual methods. This is extremely useful in industries like aerospace and automotive, where there is a high demand for precision-made parts. A job that might take days to complete manually can often be done in just a few hours using CNC technology.

Another major advantage of CNC machining is that it cuts down on material waste. Traditional machining can leave behind large amounts of unused material, but CNC machines are designed to make the most of every piece. They follow optimized cutting paths, which helps minimize excess material. This not only saves money but also reduces environmental waste, making CNC machining a more sustainable option.

Additionally, CNC machining helps businesses save on labor costs. In traditional factories, many workers are needed to manually cut, shape, and finish parts. With CNC machining, a few operators can oversee multiple machines at once, reducing the need for a large workforce. This makes CNC machining more affordable for manufacturers while delivering high-quality production.

How Different Industries Use CNC Machining

CNC machining is used in many industries that require extreme precision and quality. Quality control is a vital part of CNC machining for complex parts. Some of the most common industries that depend on CNC technology include:

Aerospace Industry

Airplanes and spacecraft must be made with lightweight but strong materials. CNC machining helps create complex parts like turbine blades, engine parts, and structural components with perfect accuracy. Since aircraft parts must handle extreme pressure and temperature changes, they need to be made exactly right. CNC machining ensures they meet strict safety and performance standards.

Medical Devices

Medical tools and implants require extreme precision to ensure they work properly. CNC machining is used to make surgical instruments, prosthetics, and artificial joints. Since every patient is different, CNC technology allows for custom medical implants that fit perfectly. This level of detail is crucial for improving patient outcomes and quality of life.

Automotive Manufacturing

Car manufacturers use CNC machining to create engine parts, brake systems, and transmission components. With the rise of electric vehicles and fuel-efficient cars, precision-machined parts are needed more than ever. CNC machining ensures that every part meets high industry standards, making cars safer and more efficient.

Electronics and Technology

CNC machining is essential in the production of electronics, including circuit board components, heat sinks, and device enclosures. As technology advances, electronics are becoming smaller and more complex. CNC machining allows manufacturers to create precise, delicate parts that fit perfectly into modern devices without sacrificing strength or performance.

Defense and Military Applications

The defense industry uses CNC machining to make weapons, armored vehicle parts, and high-performance military equipment. These products must be incredibly strong and reliable. CNC machining ensures every piece is manufactured to exact specifications, reducing the risk of failure in critical situations.

CNC milling and CNC turning allow for precise cutting, drilling, and shaping to achieve the desired outcome. These methods help manufacturers meet tight tolerances and maintain consistent quality.

The Future of CNC Machining and Advanced Manufacturing

CNC machining continues to evolve, making production even more precise, efficient, and automated. Some of the most exciting advancements include:

- Artificial Intelligence and Smart CNC Machines: AI-powered CNC machines can adjust cutting paths automatically, reducing tool wear and improving accuracy.

- CNC Machining and 3D Printing: Hybrid manufacturing combines 3D printing with CNC machining to create detailed, complex parts faster.

- Better Cutting Tools and Materials: High-speed tools and advanced coatings improve efficiency in milling and CNC turning.

- Automated Quality Control: AI-driven inspections ensure CNC machined parts meet the highest standards before being shipped.

With these improvements, CNC machining will continue to lead the way in manufacturing processes. It allows industries to produce high precision, complex designs faster and more efficiently than ever before.

The Lasting Impact of CNC Machining

CNC machining has completely changed the way industries create complex parts. It offers precision, efficiency, and automation, making it the best choice for industries like aerospace, medical, automotive, and electronics. Whether producing small custom parts or mass-manufacturing essential components, CNC machining delivers complex geometries.

Looking ahead, innovations in artificial intelligence, hybrid manufacturing, and quality control will make CNC machining even more powerful. As technology advances, CNC machines will continue to push the limits of what’s possible, helping industries develop cutting-edge products with perfect precision. CNC machining is here to stay, making the future of manufacturing more efficient, accurate, and cost-effective than ever before.