When to Choose 5-Axis Machining for Your Project

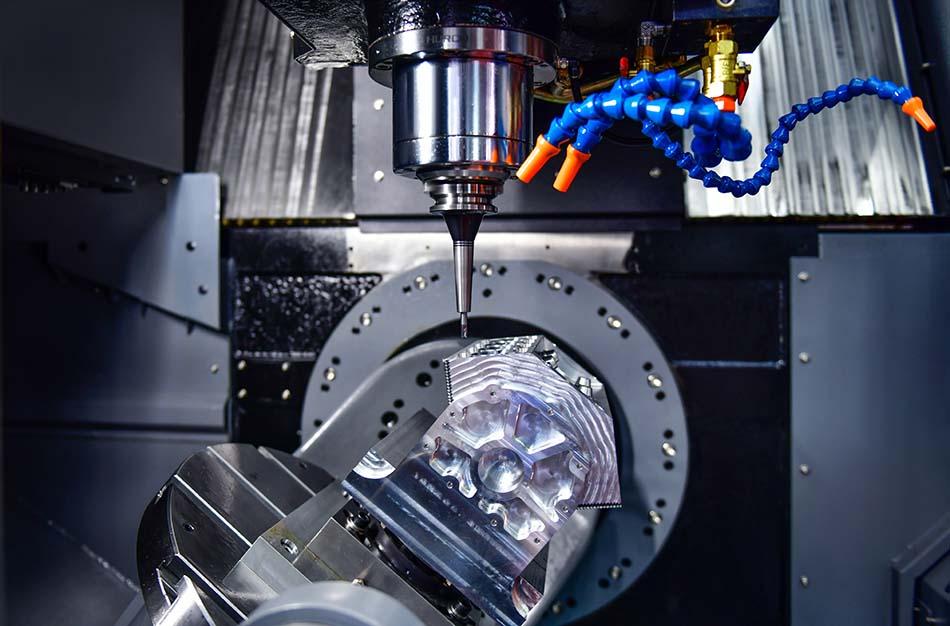

In modern manufacturing, precision and efficiency are everything. Some projects need advanced tools to handle complex shapes, tight measurements, and smooth finishes. This is where 5-axis CNC machining becomes essential. Unlike the simpler 3-axis machines, 5-axis machining allows the tool to move in five directions, making it more flexible and precise.

This blog will explain what makes 5-axis machining special, when to use it, and why it could be the perfect choice for your project. By the end, you’ll see how this technology can help create high-quality parts with less hassle.

What Makes 5-Axis Machining Special?

5-axis machining moves in five directions: up and down (Z), left and right (X), front and back (Y), plus two rotations (A and B). This flexibility allows the cutting tool to reach almost any part of the material without needing to stop and reposition.

This advanced motion makes 5-axis machining ideal for detailed designs, often using a rotary table to position the material precisely. It also uses smart software that keeps everything moving smoothly, making sure parts are cut accurately and consistently. Whether it’s for an airplane part or a medical implant, 5-axis machines deliver impressive results.

When Should You Use 5-Axis Machining?

1. Complex Shapes

If your project involves parts with complicated designs, like curves or hidden areas, 5-axis machining is a great option. For example, turbine blades for airplanes or medical implants need exact shapes that 3-axis machines can’t handle.

In the car industry, parts like exhaust systems or engine components often have tricky internal and external features. A 5-axis machine can make these in one step, saving time and reducing mistakes.

2. High Precision

For industries like aerospace, automotive, or medical, getting the exact right measurements is crucial. 5-axis machines can make parts that fit together perfectly and work well under stress.

Example: Medical devices like knee or hip implants must have precise dimensions to work properly. 5-axis machining ensures these parts meet strict requirements, making them safe and reliable.

3. Saving Time on Setups

3-axis machines often need you to stop and adjust the material to cut different sides. This takes time and can lead to mistakes. With 5-axis machines, you can work on multiple sides in one go, saving time and reducing errors.

This is especially helpful for industries that need fast results, like electronics or prototype creation. The quicker setup means you can meet tight deadlines without sacrificing quality.

4. Expensive Materials

When using costly materials like titanium or composites, wasting less is important. 5-axis machines are precise without exception, which means less scrap, better tool life, and more efficient use of materials.

Example: In aerospace manufacturing, where titanium is common, 5-axis machining ensures you get the most out of every piece, cutting costs and reducing waste.

5. Smoother Finishes

5-axis machines produce smoother surfaces, reducing the need for additional processes such as sanding or polishing. This is important for products that need to look good or perform perfectly, such as luxury car parts or medical devices.

Smooth finishes are also key in reducing drag for airplane parts or making surfaces easier to clean for medical tools. By working on all angles in one setup, 5-axis machining ensures a flawless result.

Why Use 5-Axis Machining?

- Handles Tough Jobs: Perfect for industries like aerospace, automotive, and medical.

- Saves Money Over Time: While the machines cost more, they save money by making complex parts in fewer steps.

- Boosts Productivity: One setup means faster production with consistent quality.

- Encourages Creativity: Designers can think outside the box without worrying about machining limits.

- Reduces Waste: Precision cutting means less material goes to waste, especially for expensive metals.

Is 5-Axis Machining Right for You?

Deciding on 5-axis machining depends on your project. If your part is complex, needs tight measurements, or uses costly materials, it’s probably the best choice. Industries like aerospace or medical devices often rely on 5-axis machines because precision and quality matter so much.

For simpler shapes or smaller budgets, 3-axis machining might still work well. The key is to think about what your project needs and talk to experts who know how to use these technologies effectively.

Why 5-Axis Machining Could Be Your Best Choice

5-axis CNC machining is a game-changer for projects that require high precision, detailed designs, and smooth finishes. It saves time, reduces waste, and produces parts that traditional methods can’t match. By using this technology, manufacturers can stay ahead in competitive industries and create products that stand out.

At In-House CNC, we specialize in 5-axis machining and can help you decide if it’s the right fit for your project. Reach out to us today to learn more about how we can bring your ideas to life with accuracy and efficiency. Partner with us to achieve exceptional results for your CNC projects.