Importance of CAD/CAM in CNC Machining

2 items

Menu

Services

Emergency Contact Form

Newsletter Signup!

© All rights reserved. • In-House CNC Service LLC | Privacy Policy | Terms of Service • Web Design Services In ABQ by Design it Right

2 items

© All rights reserved. • In-House CNC Service LLC | Privacy Policy | Terms of Service • Web Design Services In ABQ by Design it Right

cad cam house

In-House CNC Service LLC offers a wide range of CNC machining services to enhance the performance and longevity of CNC machines. From pre-purchase inspections to preventative maintenance, the company's experienced team provides comprehensive support to ensure optimal machine operation.

Services include ballbar calibration, bearing replacements, control system upgrades, and emergency repairs. By addressing CNC machining issues proactively, In-House CNC Service LLC helps clients minimize downtime and maintain productivity.

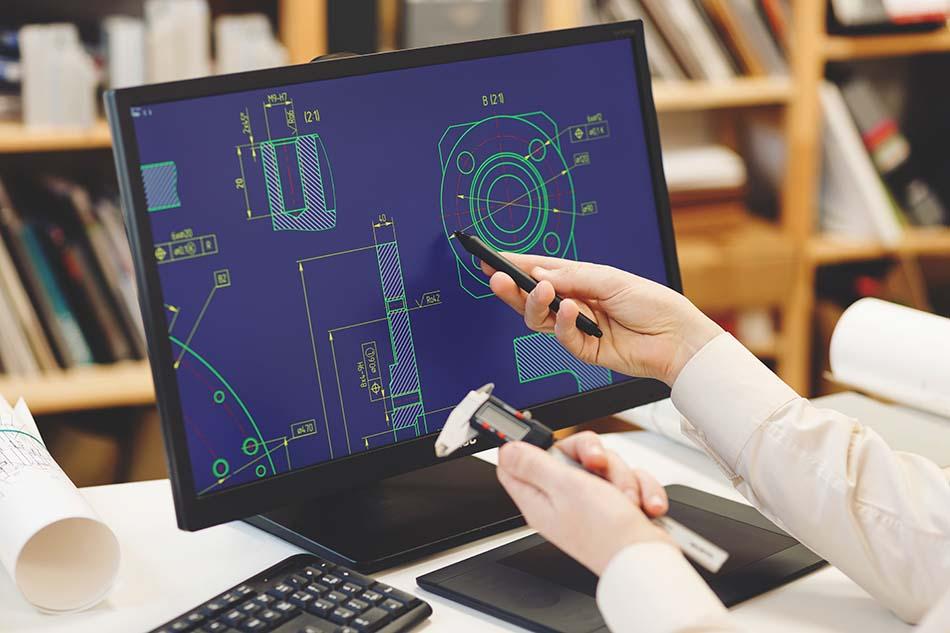

The seamless integration of CAD/CAM software is crucial for streamlining CNC operations. By leveraging advanced computer-aided design and manufacturing tools, In-House CNC Service LLC helps clients reduce lead times, eliminate errors, and optimize machining workflows.

From design to production, the company's CAD/CAM expertise ensures accurate part programming, efficient tool path generation, and real-time process monitoring. This holistic approach enables clients to achieve greater precision, repeatability, and overall CNC machining performance.

When CNC machines encounter unexpected issues, In-House CNC Service LLC provides prompt and reliable emergency support. The company's technicians are available 24/7 to address critical problems, minimizing downtime and ensuring uninterrupted production.

With a fleet of service vehicles and a well-stocked inventory of replacement parts, the In-House CNC Service LLC team can rapidly diagnose and resolve a wide range of CNC machining emergencies, from electrical failures to mechanical malfunctions.

Proactive maintenance is the key to extending the lifespan and performance of CNC machines. In-House CNC Service LLC offers comprehensive preventative maintenance services, helping clients avoid costly breakdowns and maintain optimal machine efficiency.

The company's preventative maintenance programs include regular inspections, calibrations, and scheduled maintenance tasks tailored to each client's specific CNC equipment and production requirements. By addressing potential issues before they escalate, In-House CNC Service LLC ensures continuous productivity and minimizes the risk of unexpected downtime.