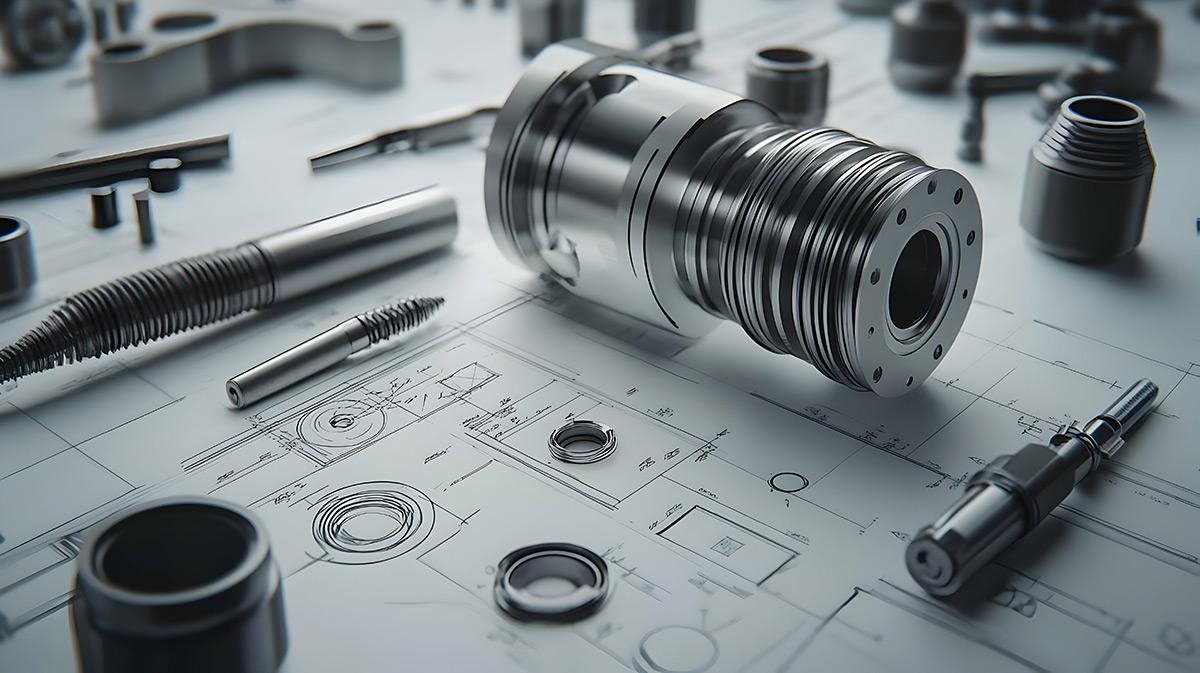

Prototyping with CNC Machining

2 items

Menu

Services

Emergency Contact Form

Newsletter Signup!

© All rights reserved. • In-House CNC Service LLC | Privacy Policy | Terms of Service • Web Design Services In ABQ by Design it Right

2 items

© All rights reserved. • In-House CNC Service LLC | Privacy Policy | Terms of Service • Web Design Services In ABQ by Design it Right

CNC prototyping offers a range of benefits for businesses and product designers. It enables rapid creation of functional prototypes, allowing for quick testing and iteration. CNC machining also provides high precision and consistent quality, ensuring accurate representations of the final product.

Additionally, CNC prototyping is cost-effective compared to traditional manufacturing methods, making it accessible for businesses of all sizes. It also reduces lead times, enabling faster time-to-market for new products.

CNC prototyping plays a crucial role in the product development process. It allows designers and engineers to validate their concepts, test functionality, and gather crucial feedback before committing to full-scale production.

By incorporating CNC prototyping at various stages of the development cycle, companies can identify and address design flaws, optimize product features, and ensure the final product meets customer requirements. This iterative approach helps reduce risk, minimize costly mistakes, and accelerate the path to market.

Selecting the appropriate CNC machining services is essential for successful prototyping and product development. Factors to consider include the provider's expertise, machine capabilities, turnaround times, and quality control measures.

A reliable CNC service partner can offer guidance on material selection, design optimization, and post-processing, ensuring the prototypes meet the desired specifications and requirements. Partnering with an experienced CNC provider can streamline the prototyping process and contribute to the overall success of the product development initiative.

Integrating CNC prototyping into your product development workflow can enhance efficiency and agility. By establishing a seamless process for obtaining CNC-machined prototypes, teams can quickly validate design concepts, gather user feedback, and make informed decisions throughout the development cycle.

Effective integration of CNC prototyping involves establishing clear communication channels, defining project timelines, and aligning the prototyping process with your overall product development strategy. This holistic approach can lead to faster iterations, improved product quality, and a more streamlined path to market.