In-House CNC Service:

Ballscrew Repair and Installation Service

Why Choose Our Premier Ballscrew Repair, Replacement, and Installation Service?

In-House CNC Service:

Ballscrew Repair and

Installation Service

Why Choose Our Premier Ballscrew Repair, Replacement, and Installation Service?

Restore CNC Precision with In-House CNC’s Ballscrew Repair Service

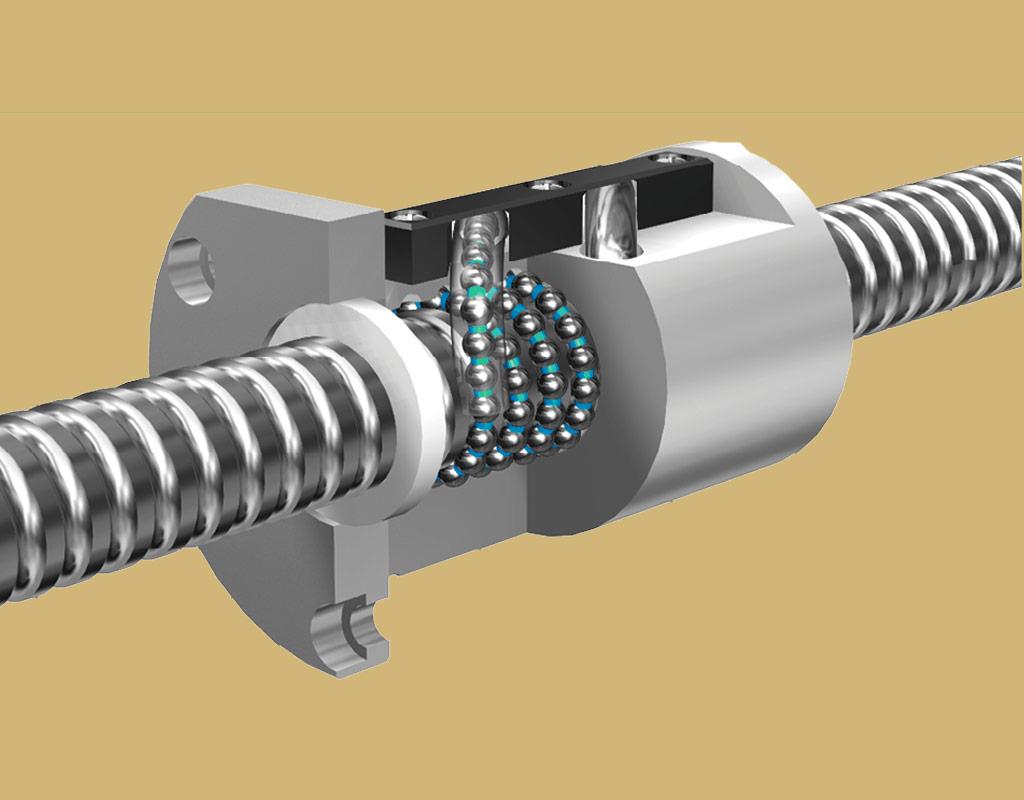

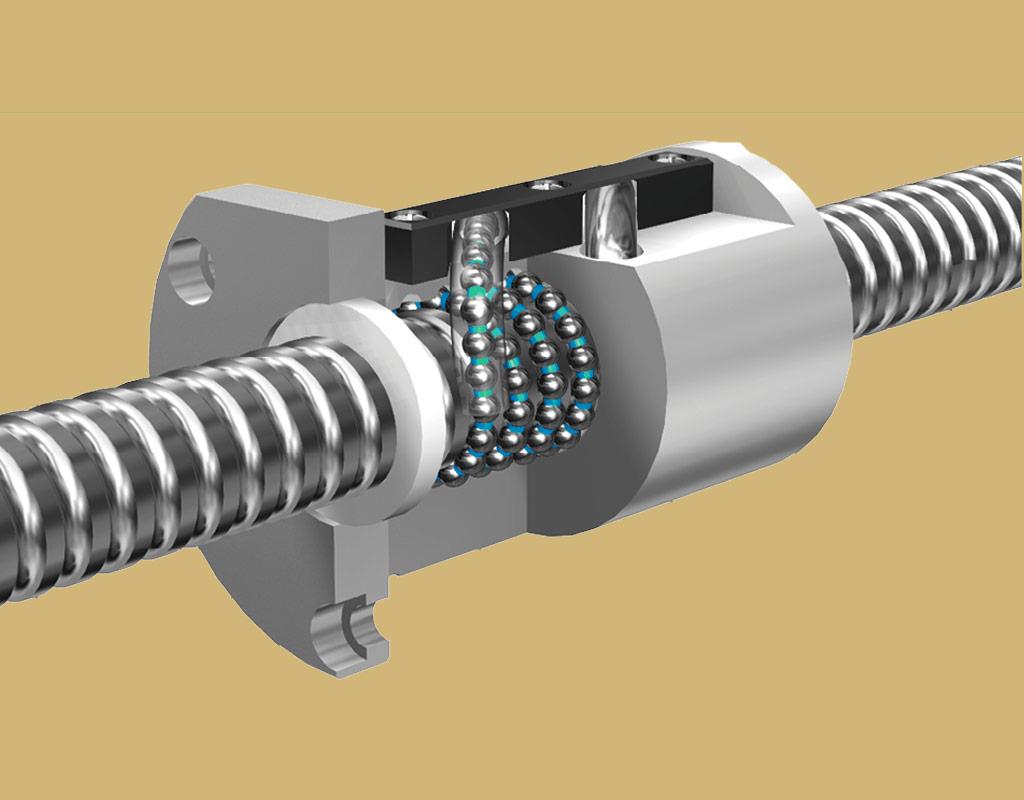

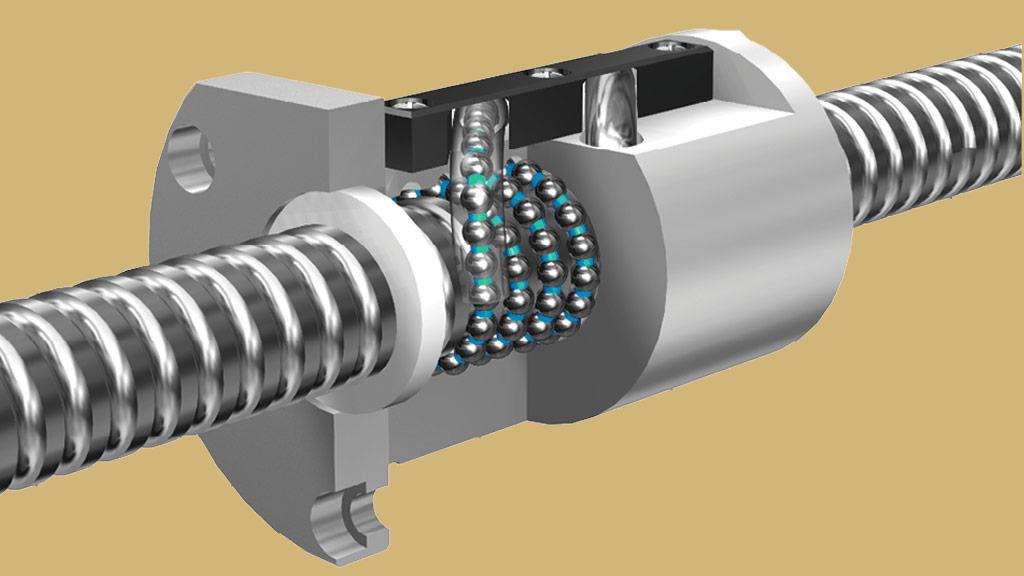

At In-House CNC, we understand that ballscrews play a vital role in CNC machine performance. That’s why we offer expert repair services to restore precision, efficiency, and reliability. As a trusted provider of CNC ballscrew repair, we use advanced diagnostics and precision techniques to extend the lifespan of your equipment.

Our comprehensive approach identifies wear, misalignment, and damage, ensuring your ballscrew operates with optimal accuracy and smooth motion. With our industry expertise and high-quality repairs, we help you reduce downtime, improve machining performance, and protect your investment.

Key Features of Our Ballscrew Repair Service

Comprehensive Inspection & Expert Diagnosis

At In-House CNC, we begin with a thorough assessment of your ballscrew assembly, identifying wear, damage, and misalignment that may be affecting performance. Our expert technicians conduct precise diagnostics to determine the root cause of issues, ensuring the most effective repair solutions.

Precision Repair & Cost-Effective Solutions

Rather than opting for full replacement, our ballscrew repair services provide a cost-effective alternative that restores function while minimizing downtime. Using advanced reconditioning techniques, we repair or replace worn components, ensuring smooth motion, accurate positioning, and extended machine lifespan.

Detailed Testing & Performance Validation

At In-House CNC, we recognize that precision and accuracy are critical in ballscrew performance. That’s why our Ballscrew Repair Service includes thorough testing and validation to ensure your CNC machine operates with maximum reliability and efficiency.

We take a comprehensive approach, using advanced testing procedures to verify alignment, smooth motion, and load-bearing capability. By rigorously evaluating key performance metrics, we guarantee your ballscrew meets the highest operational standards.

Our goal is to provide precise, transparent, and reliable repairs, giving you the confidence that your CNC machines are performing at their absolute best.

The Ballscrew Repair Process

Inspection and Assessment

Our ballscrew repair process begins with a detailed inspection, where we assess wear, misalignment, and potential damage. Using precision measurement tools, we identify issues affecting accuracy and performance.

Disassembly and Cleaning

Once assessed, the ballscrew is carefully disassembled, and each component—lead screws, ball nuts, and bearing supports—is thoroughly cleaned. This removes contaminants that could contribute to premature wear or motion inefficiencies.

Reconditioning and Component Replacement

Worn parts are either reconditioned or replaced using state-of-the-art techniques. We ensure that each rebuilt ballscrew assembly meets strict performance and durability standards, restoring smooth and precise movement.

Reassembly and Final Testing

After reconditioning, the ballscrew is meticulously reassembled and undergoes rigorous testing to verify accuracy, alignment, and performance. Our quality assurance process ensures that your CNC machine operates at peak efficiency once the repair is complete.

Choosing the Right Ballscrew Repair Service

Expert Technicians & Precision Repairs

Selecting the right ballscrew repair service is essential for ensuring long-term machine accuracy and reliability. At In-House CNC, our skilled technicians specialize in precision repairs, utilizing advanced tools and techniques to restore optimal performance.

Comprehensive Services & Advanced Equipment

We offer a full range of repair solutions, from reverse engineering and component replacement to complete ballscrew rebuilds. Our use of cutting-edge diagnostic and calibration equipment ensures that every repair meets the highest industry standards.

Fast Turnaround & Minimized Downtime

Machine downtime impacts production efficiency. That’s why we prioritize fast lead times without compromising on quality. Our efficient repair process helps you reduce downtime and keep operations running smoothly.

At In-House CNC, we are committed to delivering precision-driven, high-quality repairs that extend the lifespan of your CNC machines.

Commitment to Quality and Customer Satisfaction

At In-House CNC, we prioritize quality, precision, and customer satisfaction in every ballscrew repair service we provide. Our team follows strict industry standards, using high-quality components and expert techniques to ensure long-lasting performance.

We believe in a customer-first approach, offering transparent communication, expert guidance, and tailored repair solutions to meet your specific needs. Whether it’s a minor reconditioning or a full rebuild, we go above and beyond to deliver exceptional results that exceed expectations.

With In-House CNC, you can trust that your CNC machines are in the hands of experienced professionals dedicated to keeping your equipment operating at peak efficiency.

Partner with In-House CNC Service for Ballbar & Laser Calibration

At In-House CNC, we specialize in precision-driven ballscrew repair, replacement, and installation services that restore your CNC machines to peak performance. With our expertise, cutting-edge equipment, and commitment to quality, we provide reliable solutions that keep your operations running smoothly.

Whether you need a repair to extend your ballscrew’s lifespan, a full replacement, or professional installation, our team ensures the highest level of accuracy and efficiency. Contact us today to discuss your ballscrew service needs and get your CNC machine back to optimal performance.

Keep Your CNC Machines Running with Reliable Ballscrew Repair

When a ballscrew starts to fail, accuracy suffers, friction increases, and production slows down. Ignoring the signs can lead to costly breakdowns and unplanned downtime, disrupting your entire operation.

At In-House CNC, we specialize in precision ballscrew repair, replacement, and installation, ensuring your machines stay in top working condition. Avoid delays and unexpected failures—restore smooth, accurate motion with expert repair solutions today.